Fluid Thinking, Thermal Innovation

We are TI Fluid Systems: the industry leader in thermal solutions and fluid systems for vehicle manufacturers across the world.

Empowering the future of mobility

TI Fluid Systems designs and manufactures thermal management and fluid handling systems that improve efficiency, performance and sustainability for forward-thinking organisations worldwide.

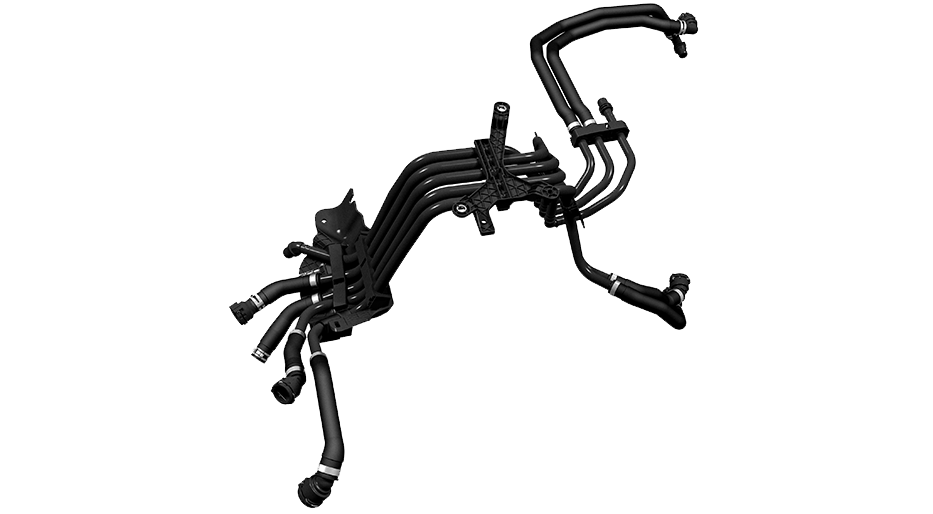

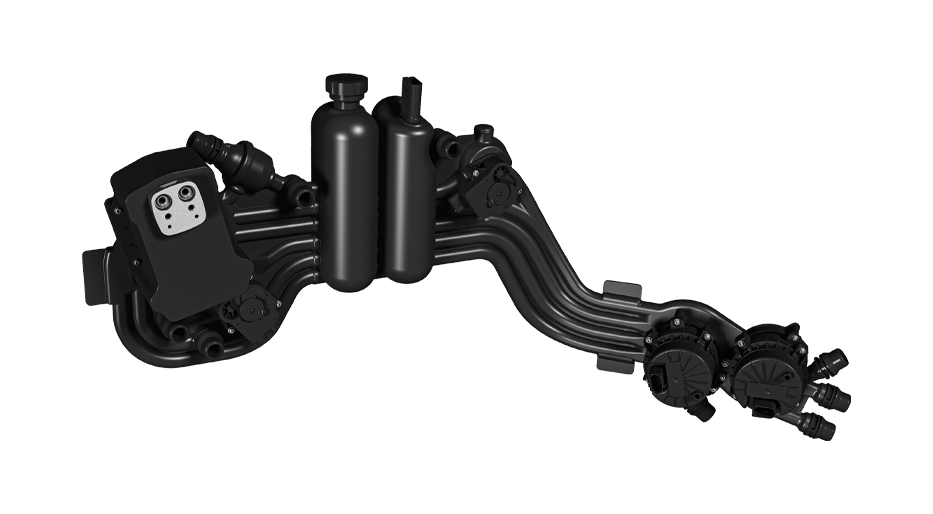

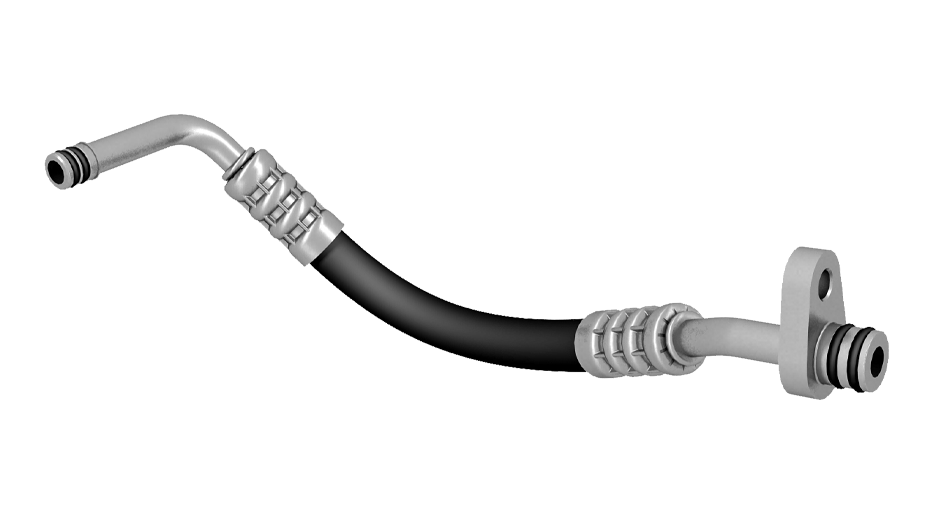

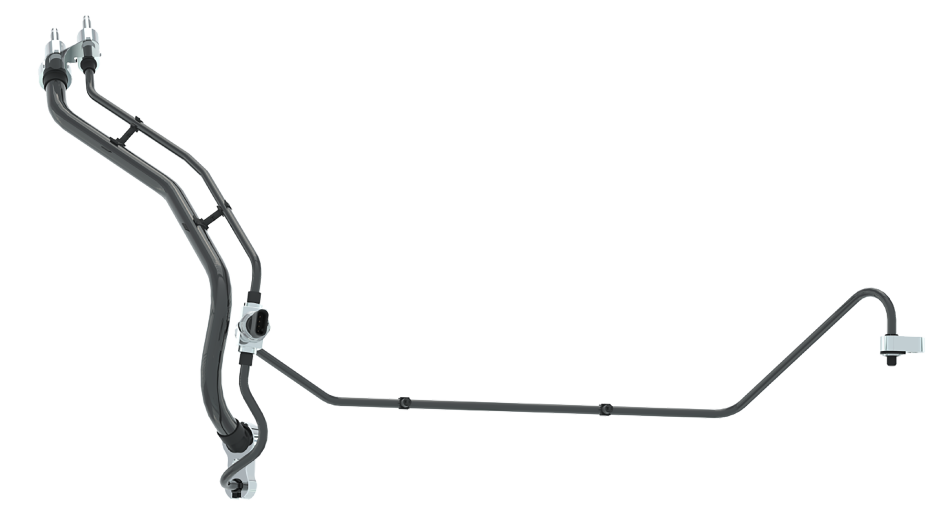

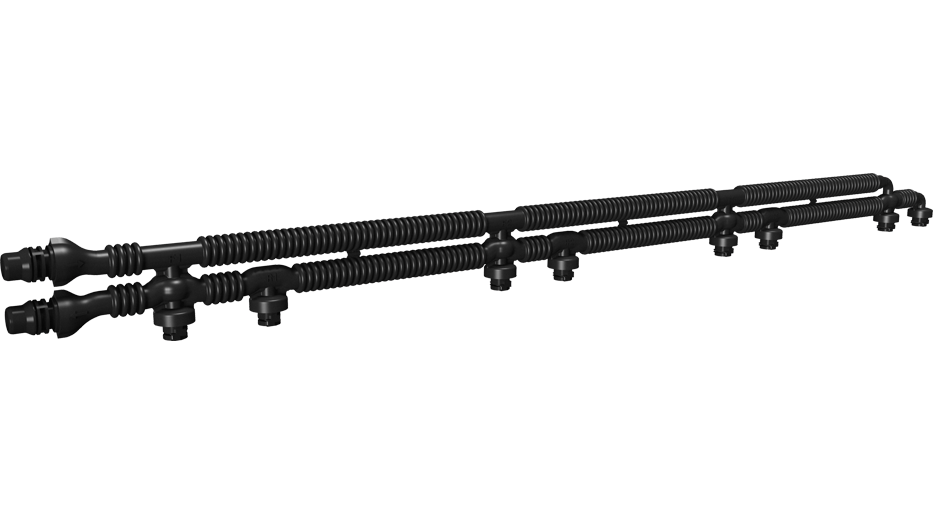

Products

Working across fluid carrying systems and thermal technologies to provide complete fluid solutions, we design and manufacture high-quality, high-efficiency products for automakers producing the vehicles of today and tomorrow.

Sustainable Fluid Solutions

We have always developed products with increased efficiency and lower emissions in mind. Now, we’re leading the shift to electrification with tailored solutions that enable our customers to lower their impact further without sacrificing quality.

Innovation-Led Mobility Technology

Our five global technical centers and seven regional support centers drive our research and development efforts, enabling us to find solutions to the industry’s most complex challenges.

Innovation for the wider world

Our Industrial Products division harnesses TI Fluid Systems’ pioneering fluid management technologies for Battery Energy Storage, Fuel Cell, Commercial Vehicle and Off-Highway applications.

News

Catch up on the latest TI Fluid Systems news and updates.

Shape the Industry’s Future With Us

We’re looking for the next generation of engineers and innovators to create a more sustainable, efficient future for us all.

Innovation-Led Mobility Technology

Our five global technical centers and seven regional support centers drive our research and development efforts, enabling us to find solutions to the industry’s most complex challenges.